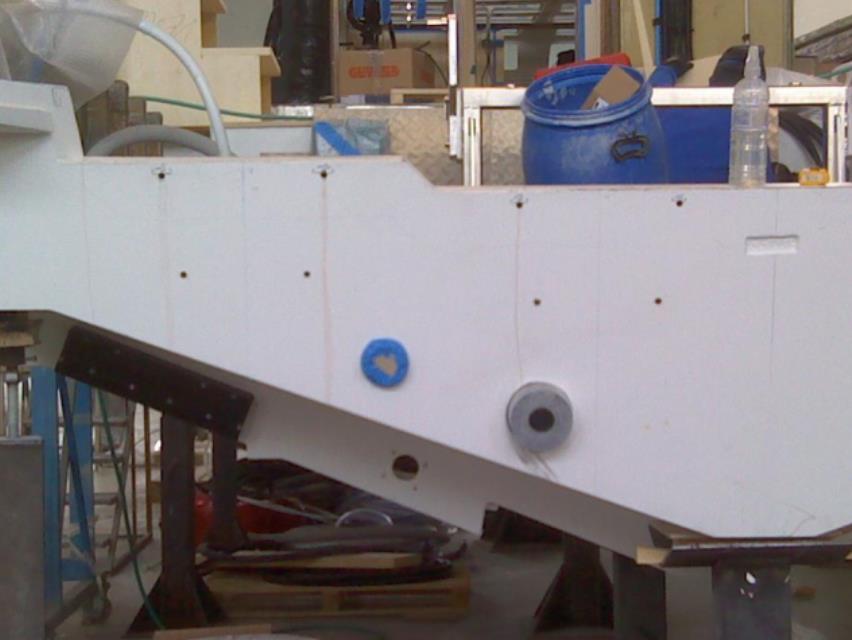

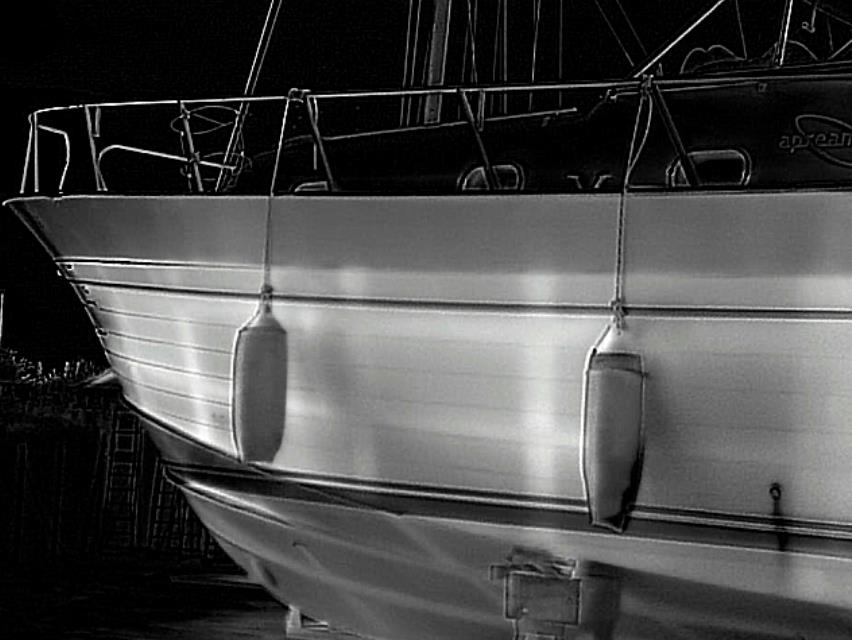

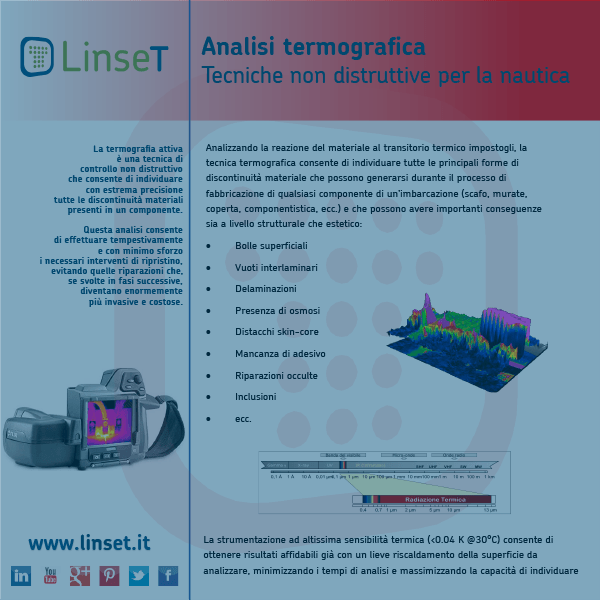

Thermography is a non-destructive testing technique that accurately detects all material discontinuities present in a component. This analysis allows for prompt and effortless restoration interventions, avoiding repairs that, if conducted in subsequent stages, would become significantly more invasive and costly.

For instance, a typical application is the identification of voids within the skin-coat layer. Such a defect is quite common (especially if the skin-coat is manually applied) and relatively easy to rectify during the manufacturing phase. However, if left unaddressed, it can potentially damage the final paintwork (incurring substantial restoration costs and compromising the appearance).

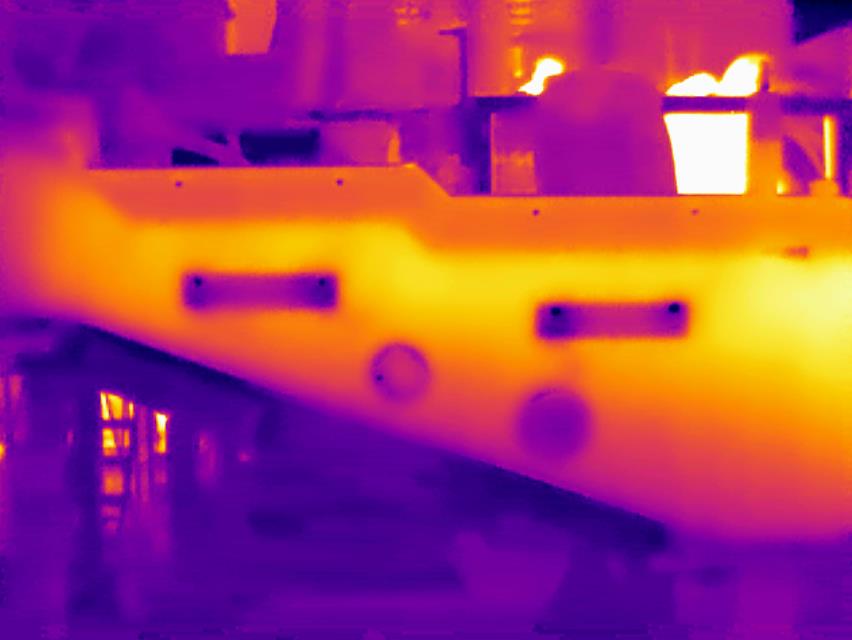

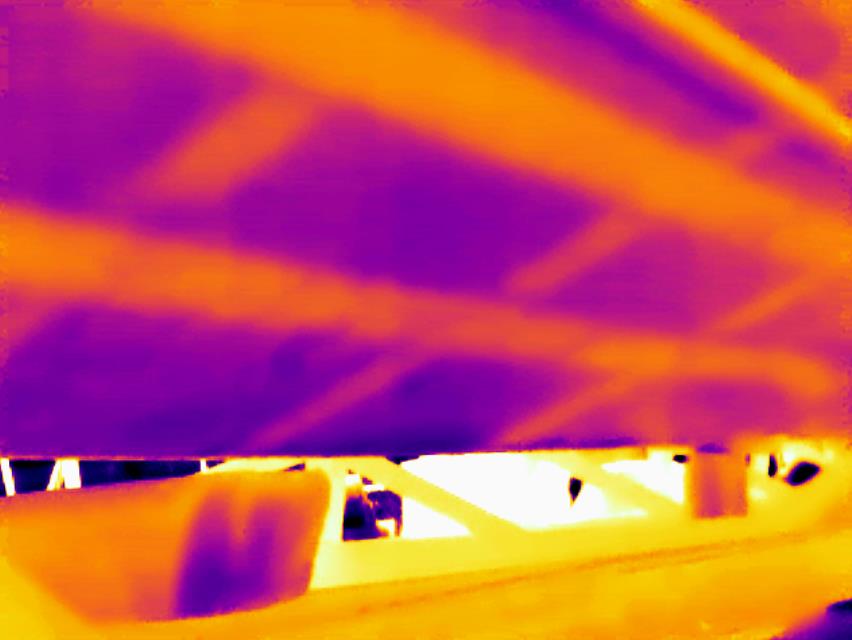

By analyzing the material’s response to thermal changes imposed on it, thermography enables the detection of various forms of material discontinuities that can arise during the production of any boat component (hull, sidewalls, deck, components, etc.), with significant structural and aesthetic consequences. Some examples include:

- Surface bubbles

- Interlaminar voids

- Delaminations

- Presence of osmosis

- Skin-core detachment

- Lack of adhesive

- Hidden repairs

- Inclusions

The highly sensitive thermal instrumentation (<0.045 K @30°C) allows reliable results even with slight surface heating for analysis, minimizing analysis times and maximizing defect detection capabilities.

When combined with ultrasound technology, the effectiveness of the analyses is further enhanced. The versatility of thermography (a surface technique capable of investigating large areas seamlessly) is complemented by the precision of ultrasound (a volumetric technique that can thoroughly examine the details and depths where thermography has identified anomalies).