Mechanical tests

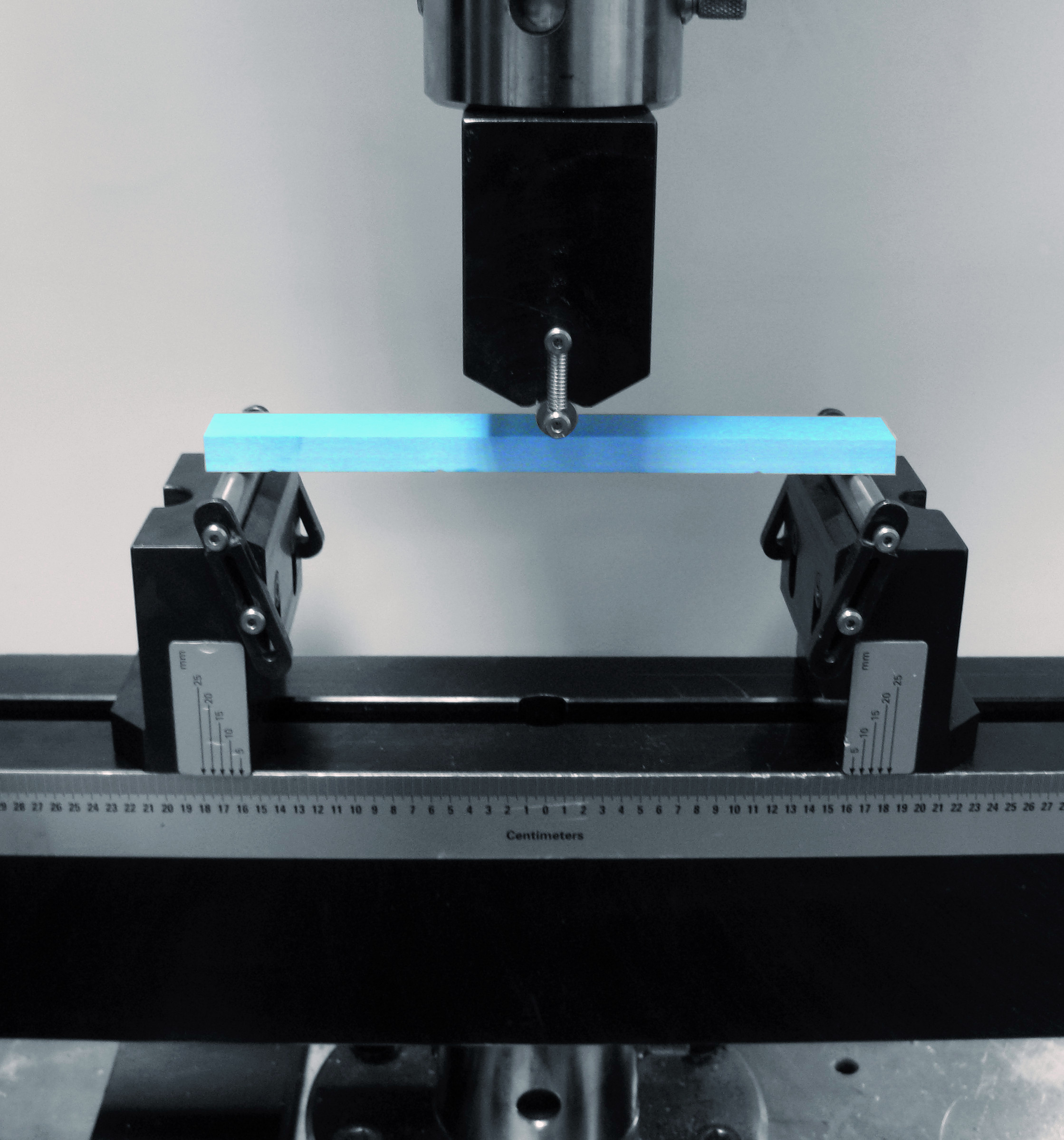

Linset’s mechanical laboratory is equipped with an electromechanical dynamometer capable of applying loads up to 250 kN.

Tests are carried out in accordance with the standards specified by the main international regulations (ASTM, ISO, etc.).

Samples are prepared using a CNC milling machine to achieve the desired geometry.

The list of tests (not exhaustive) allows for a comprehensive mechanical characterization of the tested component.

Thermal analysis

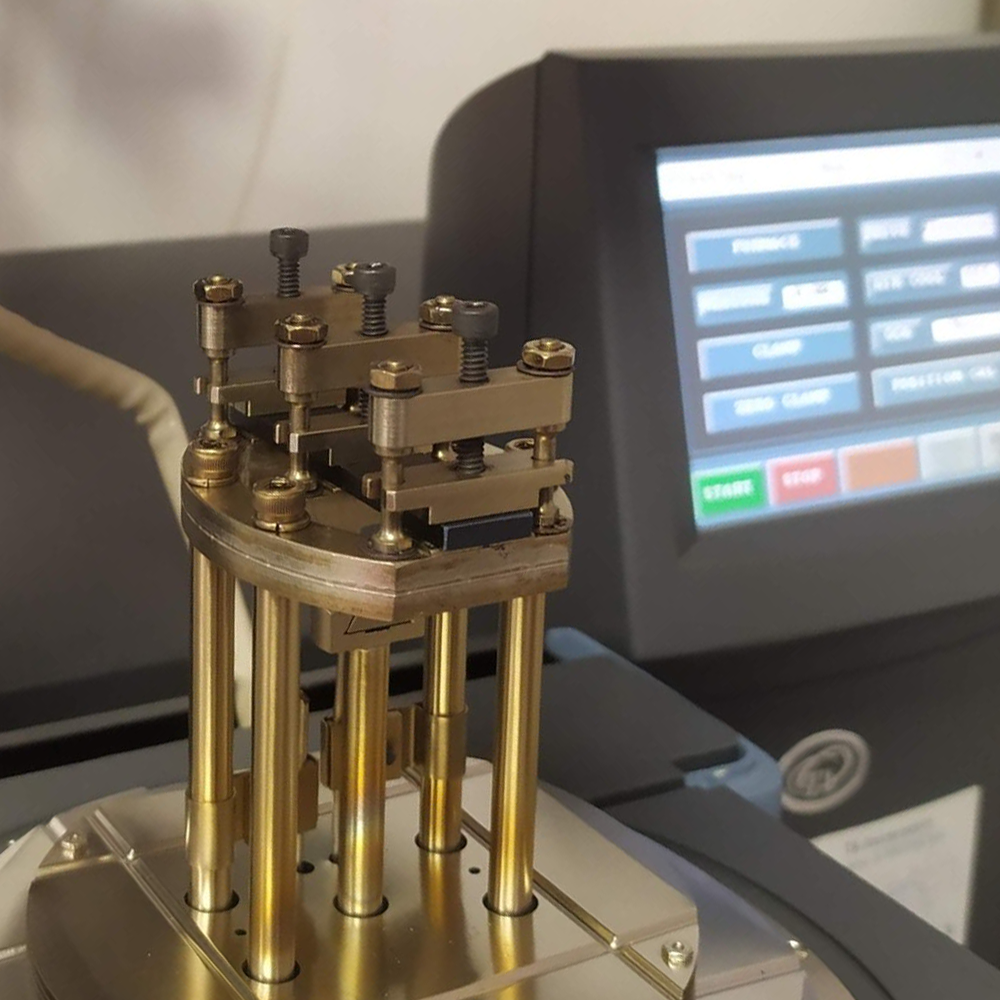

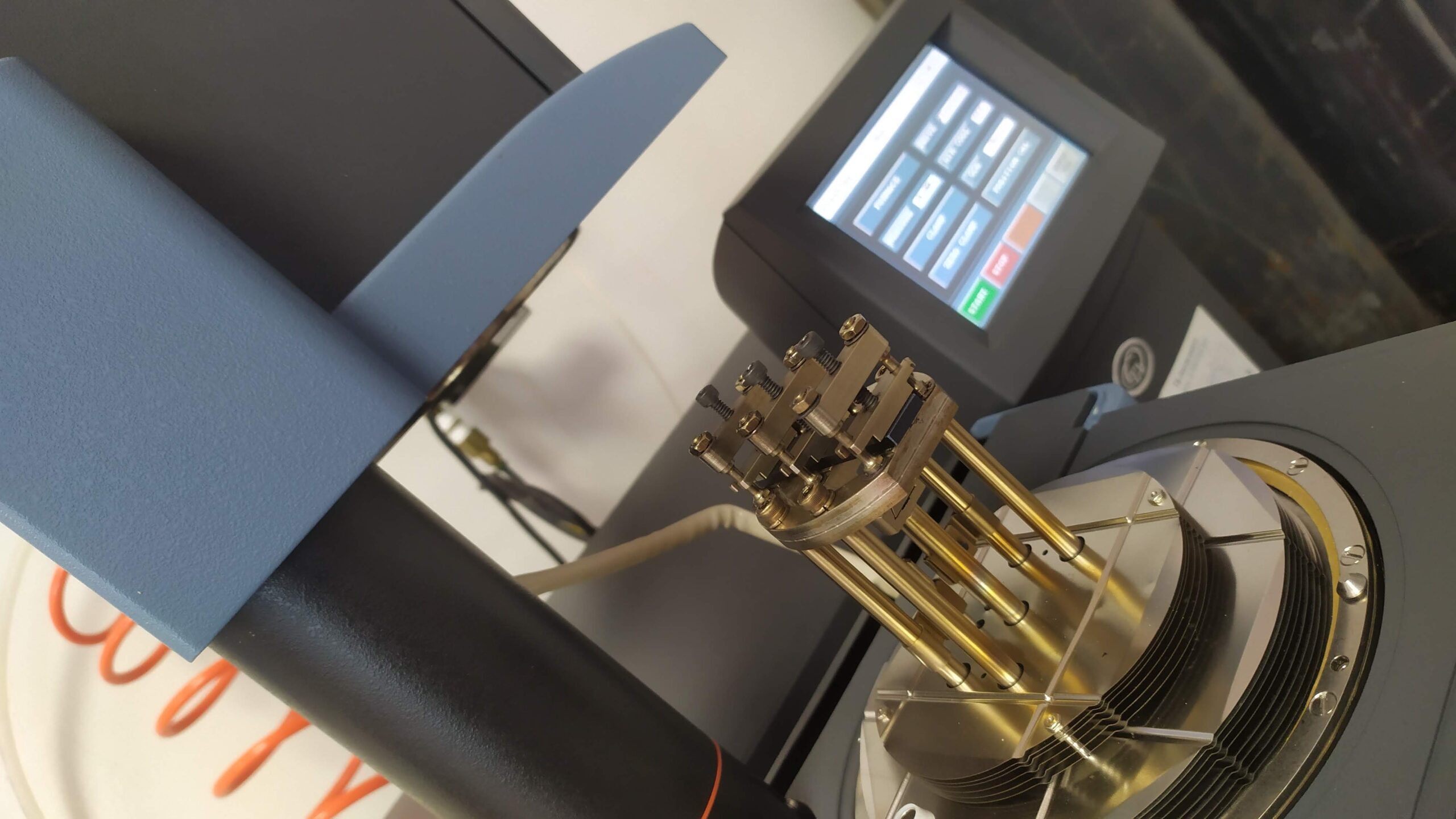

Linset’s thermal analysis laboratory is equipped with state-of-the-art instrumentation for comprehensive material characterization. Specifically, the following analysis techniques can be implemented:

DSC – Differential Scanning Calorimetry

DMA – Dynamic Mechanical Analysis

TMA – Thermo-Mechanical Analysis

Tests are conducted in accordance with the standards specified by the main international regulations (ASTM, ISO, etc.).

Chemical-Physical Testing

Linset’s materials chemical-physical analysis laboratory is a specialized facility equipped with advanced instrumentation that performs tests and measurements on a wide range of samples.

The laboratory experts use analytical techniques to determine the chemical composition of materials, identifying the elements present and their proportions.

We provide essential data to assess material quality, identify chemical substances, monitor thermal stability, and evaluate material performance under different conditions.

Customized tests

In the laboratory, specific tests are performed to evaluate the mechanical properties, such as tensile strength, flexural strength, and hardness of composite materials.

Thermal properties, chemical resistance, and moisture absorption are also analyzed. We employ advanced analysis methods to study the structure and morphology of composite materials.

Based on the client’s requirements, we can design customized tests to accommodate non-standard requests.