Linset has expanded its range of Non-Destructive Testing (NDT) methods through the use of ultrasound technology, which has become a standard for Quality Control in the field of dimensional analysis and structural integrity verification of artifacts.

The technique of measuring thickness using ultrasound has now become a requirement and often a mandate in numerous regulations across various sectors (such as the “Rules for the Classification of Pleasure Yachts” published by RINA).

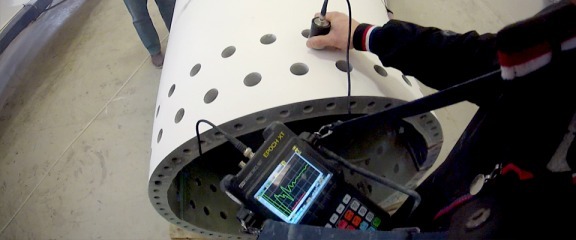

Our state-of-the-art equipment serves as both a thickness gauge and a defect detector. Its flexibility allows for in-situ and in-process analysis without the need to interrupt the manufacturing processes or alter the state of the artifact.

Ultrasound technology enables Linset to:

- Measure the thickness of the artifact (and the depth of any inserts)

- Evaluate the quality characteristics of the artifact (such as the impregnation ratio in a composite)

- Identify potential defects like cracks, porosity, and delaminations, pinpointing their exact location and dimensions

- Verify the adhesive state between two substrates

La The ability to record the detected spectra also enables continuous monitoring of the component’s condition over time and the evolution of any internal defects.

The range of probes available allows us to extend analyses to a wide variety of materials, from metals to composites (both monolithic and sandwich), enabling investigation of considerable thicknesses as well as focusing on the fine details of the topmost millimeters.

Our personnel are certified for Non-Destructive Testing using Ultrasound Techniques according to the requirements set forth in the UNI EN ISO 9712 standard and the ASNT:SNT-TC-1A Recommended Practice.